Laser metal cutting

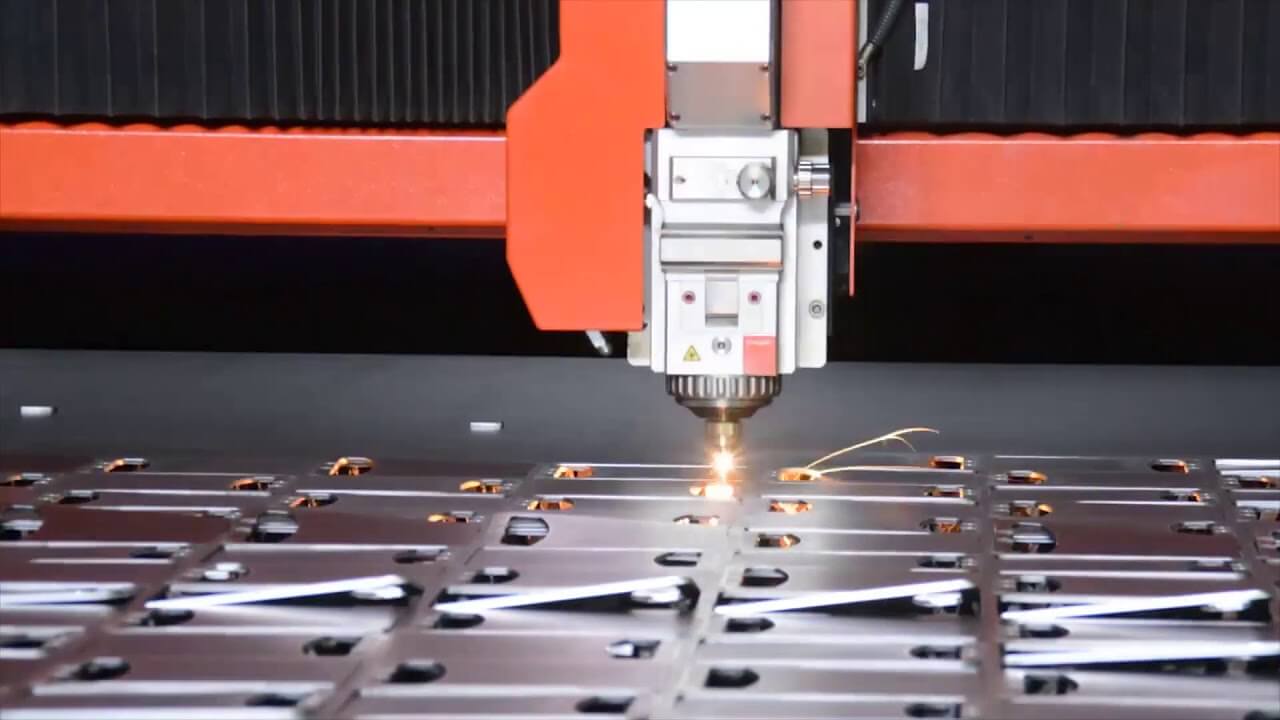

Laser cutting of metal is an innovative technology for cutting metal sheets. The method is based on the use of a focused directional laser beam as a knife.

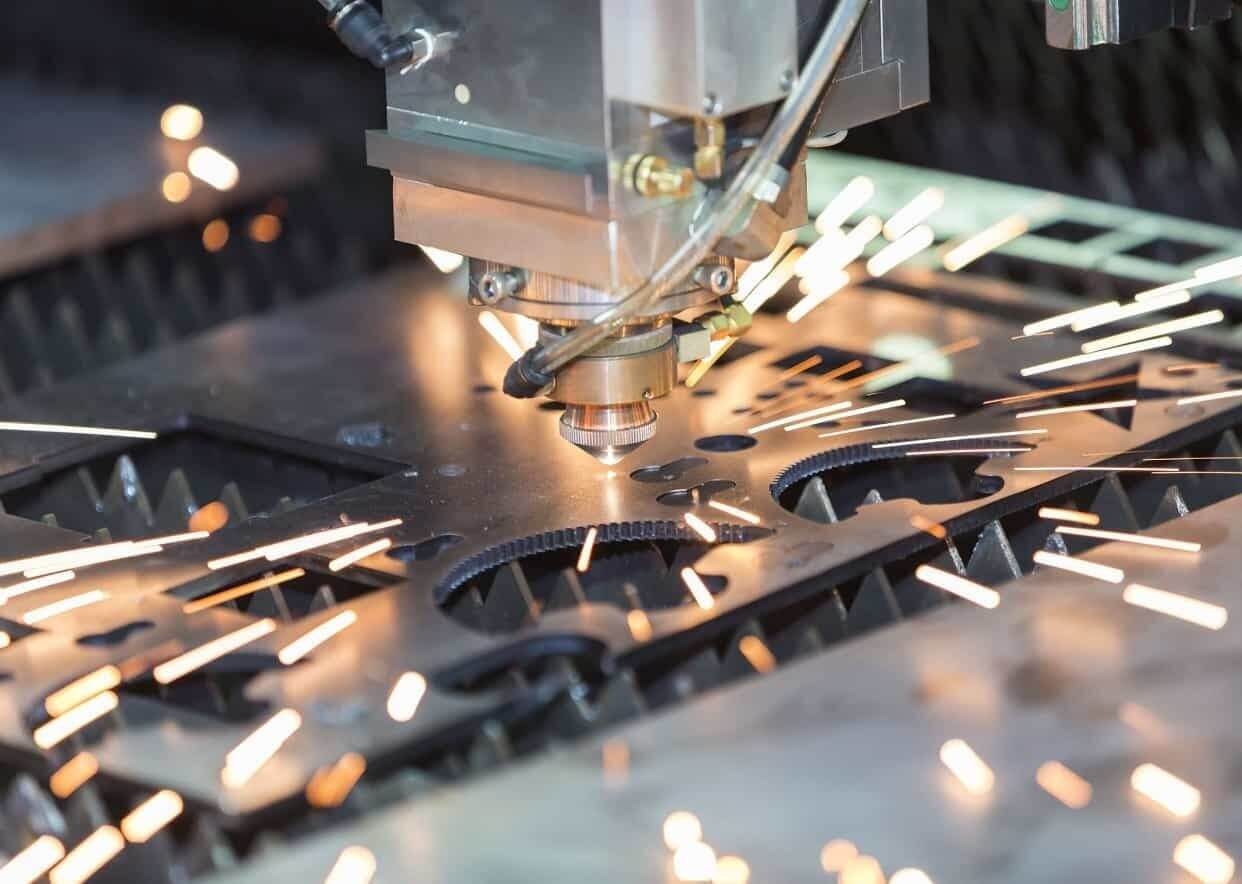

We produce high-precision laser metal cutting on CNC machines. Thanks to modern CNC machines, we cut parts of any complexity from metal. Laser cutting of sheet metal can be applied to any alloys. We cut:

- steel;

- stainless steel;

- galvanized sheet;

- aluminum;

- brass;

- copper;

- bronze.

Advantages of laser cutting of metal

Laser cutting has a number of undoubted advantages:

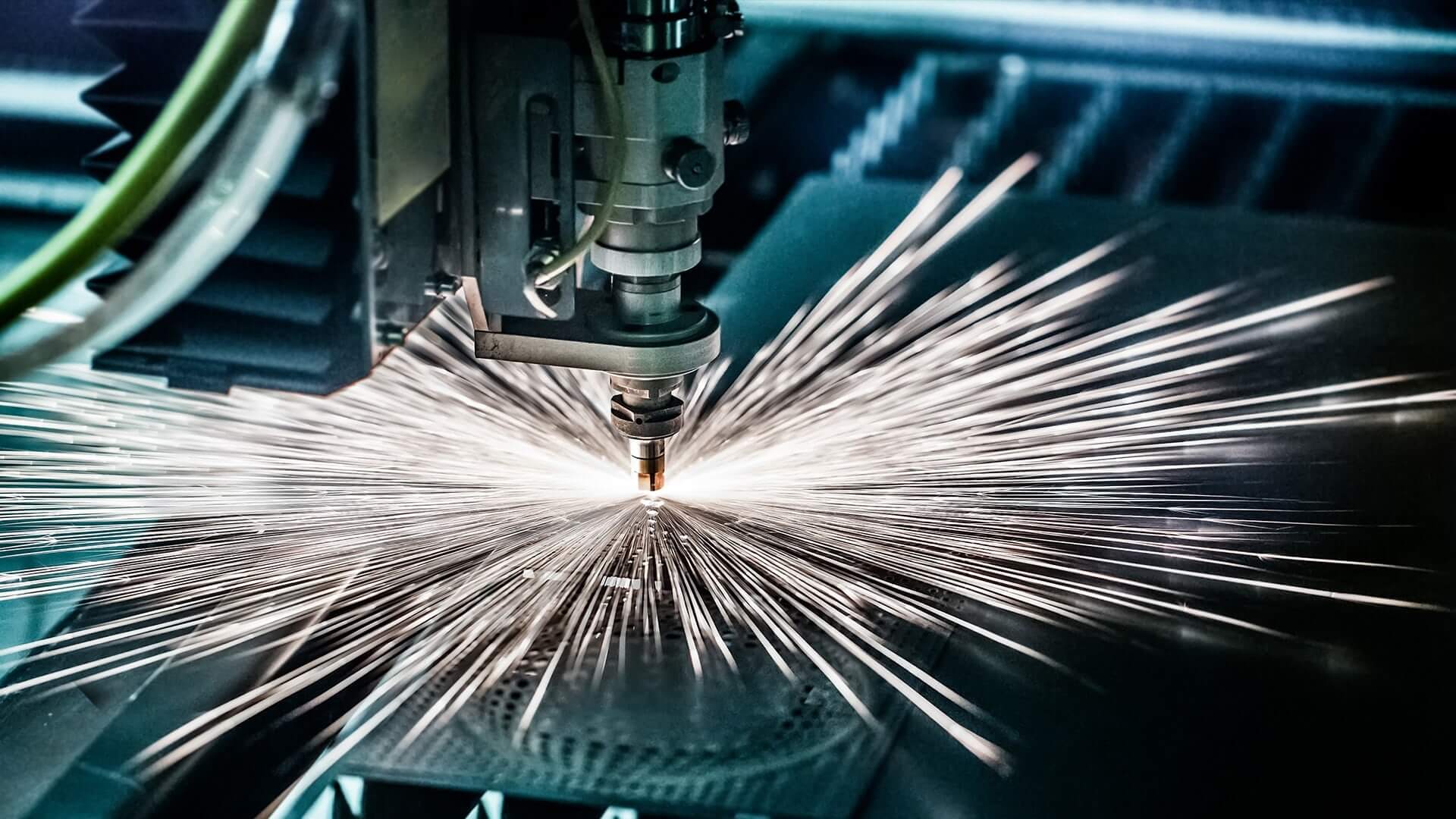

- high accuracy (up to 0.1 mm), achieved due to the possibility of perfect beam positioning;

- material savings achieved by removing only a small layer of material, providing a thin cut;

- no contact of the cutting tool with metal: the laser beam simply instantly burns the material through;

- formation of a contour for cutting of metal by means of the computer program;

- no configurations of physical parameters of the material;

- efficiency: time of cutting of a sheet considerably decreases in comparison with other methods.

In addition, the advantages of the method include the ability to cut without overheating and deformation of the edges. Heating occurs locally, at the point of contact of the laser beam, and the surrounding space is quickly cooled by air flow.

Need to cut metal sheets urgently? Laser metal cutting is what you need! We work with a variety of sheets and alloys.

LezoMetal specialists will do the job at reasonable prices and in the shortest possible time!

How is laser cutting of metal?

The parameters of the operation are determined using a computer program: inaccuracies are completely eliminated, even if you need to cut a part of a very complex configuration.

Focusing with the help of special mirrors at a certain point, the beam creates a high temperature on the surface of the product, heating it to +700 ° C. The metal instantly melts and cuts.

Performing laser cutting of metal, the workpiece comes out with the most accurate cut and smooth edges that do not require further processing.

The speed of the installation is set in accordance with the thickness of the alloy sheet, as well as its composition, the quality of the treated surface remains ideal.

Why you need to choose us?

-

Quality and reliability

All parts manufactured by us are guaranteed to be durable and wear-resistant.

-

Optimal timing

Thanks to qualified specialists and the use of high-precision devices and software, we guarantee optimal service delivery times.

-

Delivery of orders

We deliver orders to the destination chosen by the customer.

-

Affordable cost of services

Prices for our services are available to both retail and wholesale buyers.

-

Technologies

In our work, we use the latest MasterCam software that helps us in programming and modeling parts.