Design services at Lezometal

The Lezometal company has a new service! Now we not only manufacture parts for you, but we can also design any item you want from scratch and produce test samples if necessary. Interested? Read on!

⠀

What are design services (design solutions)?

⠀

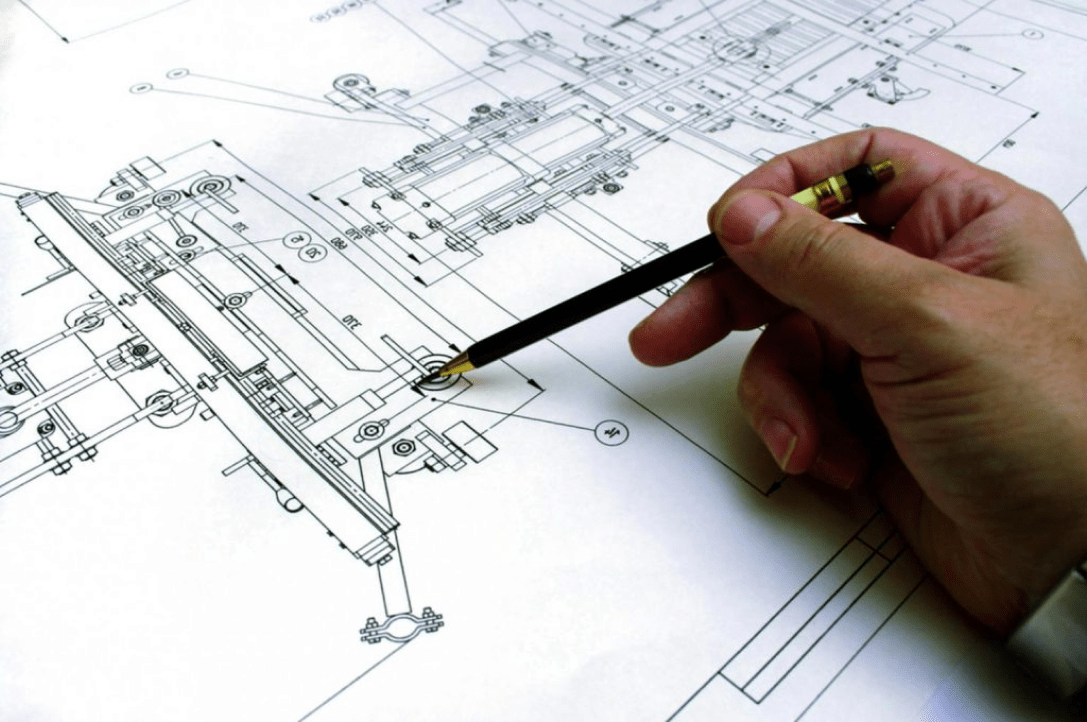

Design solutions are the most modern way to create a visualization of your part with the possibility of its subsequent manufacture. We use 3D modeling for this. This method will allow you to see the future part and, if necessary, adjust its elements in time, without spending time and money on the production of a test sample.

⠀

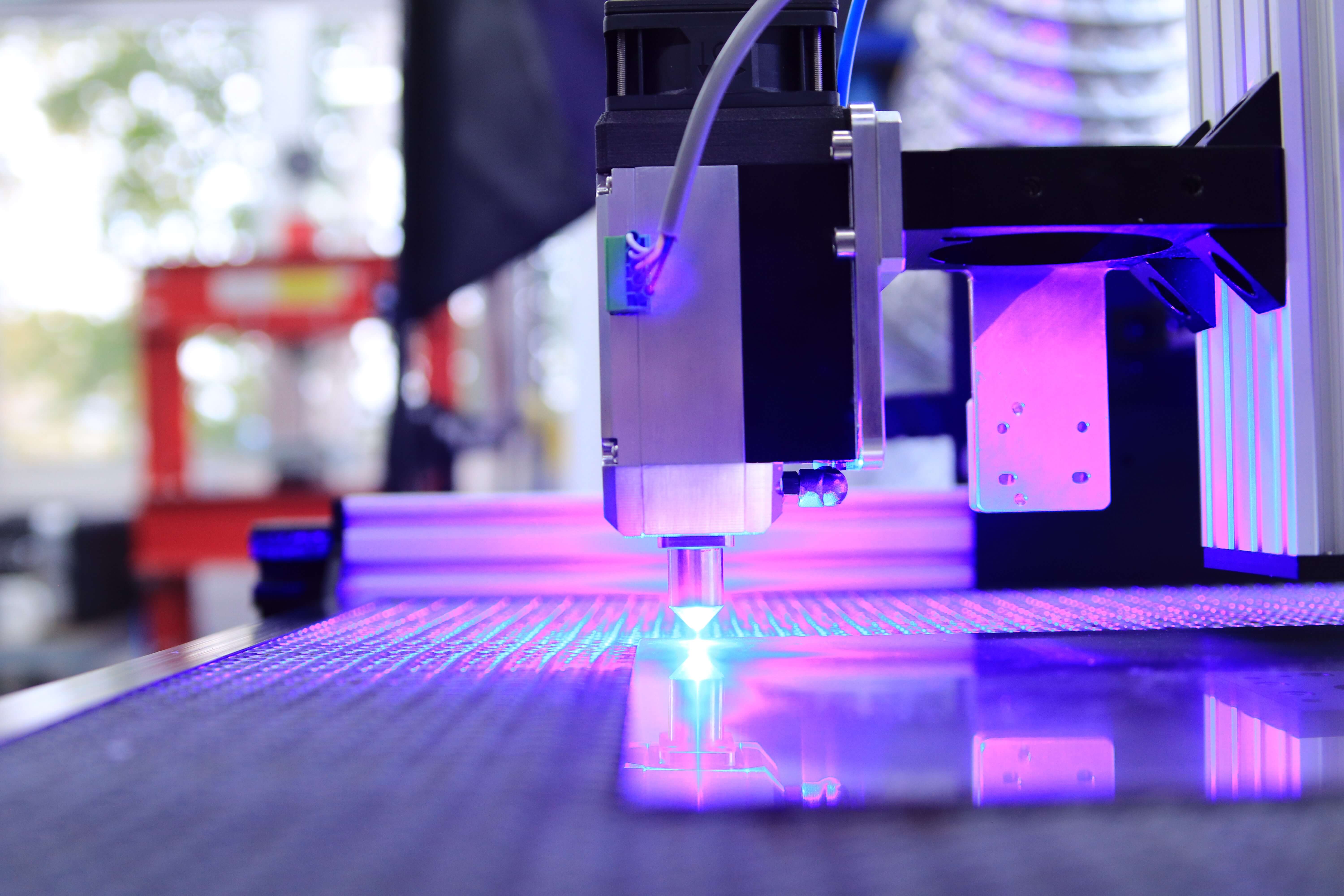

Our designers develop and implement projects for CNC machining centers, particularly robotic automatic welding, and metal laser cutting installations, which significantly increase the speed of execution of large orders. In addition, with the help of 3D models, we describe and control objects during production. Therefore, after the completion of all work, we receive the most accurate details.

What is included in design services?

⠀

Designer services include the development of drawings and 3D models of future products. In the future, you can order the manufacture of such a product in our company. We provide the following services:

- CNC metalworking;

- milling works;

- turning works;

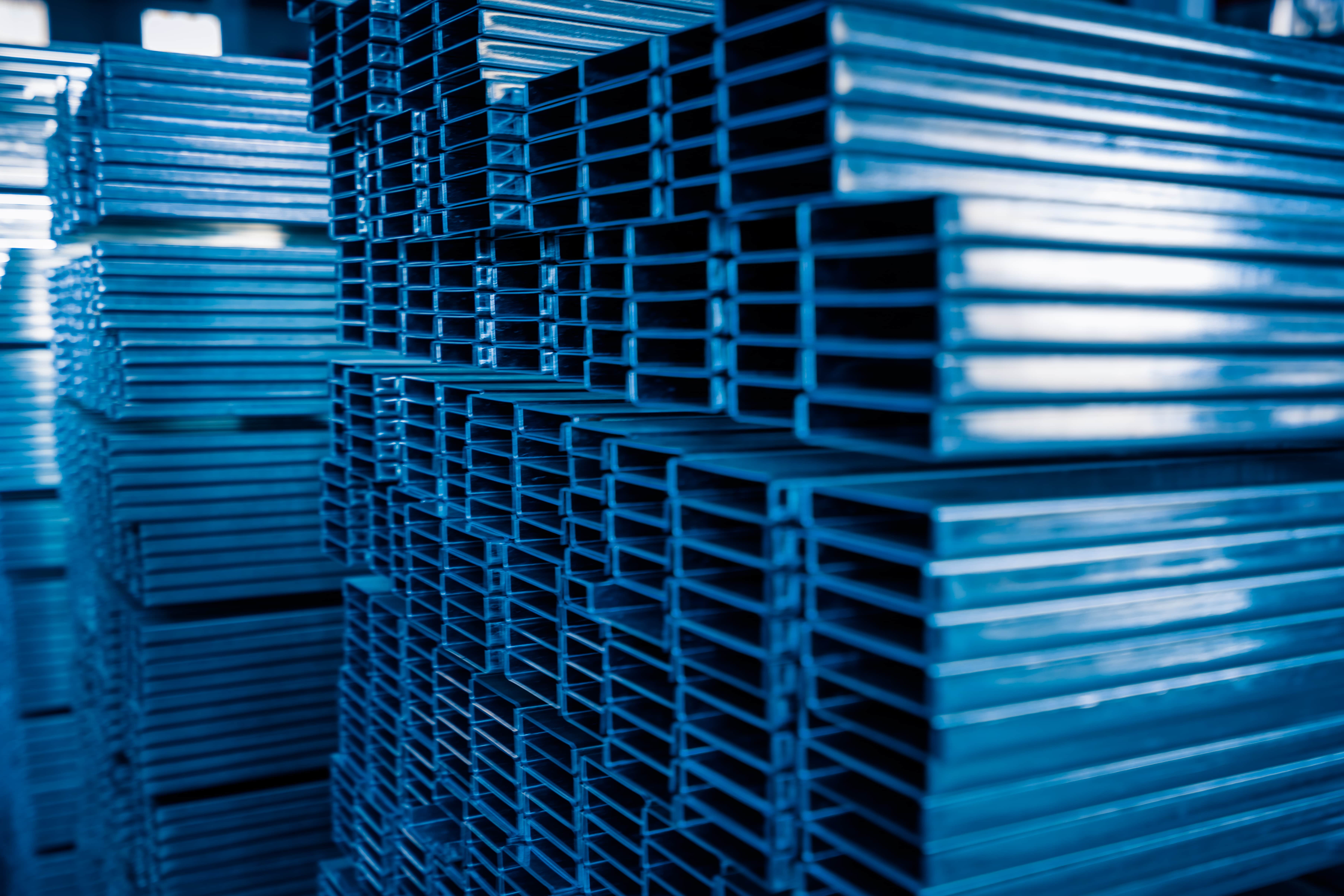

- production of parts and blanks;

- laser cutting of metal;

- metal engraving;

- metal bending.⠀

⠀

What are the advantages of Lezometal's design solutions service?

⠀

The design of parts allows:

- to reduce the time for the implementation of the project and the manufacture of parts,

- reduce the number of possible errors,

- improve the quality of design documentation.

And when using software-controlled equipment, it also allows you to prepare the necessary data in the required format. The full range of tasks solved with the help of design is extremely wide.

⠀

By contacting us, you will receive a fully functional part. After all, the range of our services and technical equipment allows us to ensure the entire production process, starting from drawings and blanks and ending with the production of entirely suitable parts.